Businesses in the competitive automotive parts manufacturing sector must maintain high-quality and compliant operations to succeed and survive.

The challenges of managing complex supply chains can impede an automotive company’s ability to compete effectively if not addressed with the proper automotive supply chain solutions.

Adopting advanced automotive supply chain solutions is an indispensable way to enhance shipment quality and optimize field operations. AutoVentive’s AV Track Sheets, which have been effectively utilized in Ford assembly plants, showcase how integrating automation and improving visibility across the supply chain network can resolve critical operational challenges.

These innovations ensure that each component meets stringent requirements set by original equipment manufacturers (automotive OEMs) and delivers on the promise of efficiency and reliability that customers demand.

Without such solutions, businesses risk falling behind in a rapidly evolving automotive industry where precision and accountability are paramount.

Ford and AutoVentive: A Partnership to Enhance Supply Chain Efficiency

Goals

Ford partnered with AutoVentive to enhance the efficiency and safety of logistics operations at its Spring Hill, Ohio, assembly plants. The collaboration aimed to replace the labor-intensive and error-prone manual process of railcar identification for transporting F-250 and F-350 utility trucks with a more streamlined and accurate system.

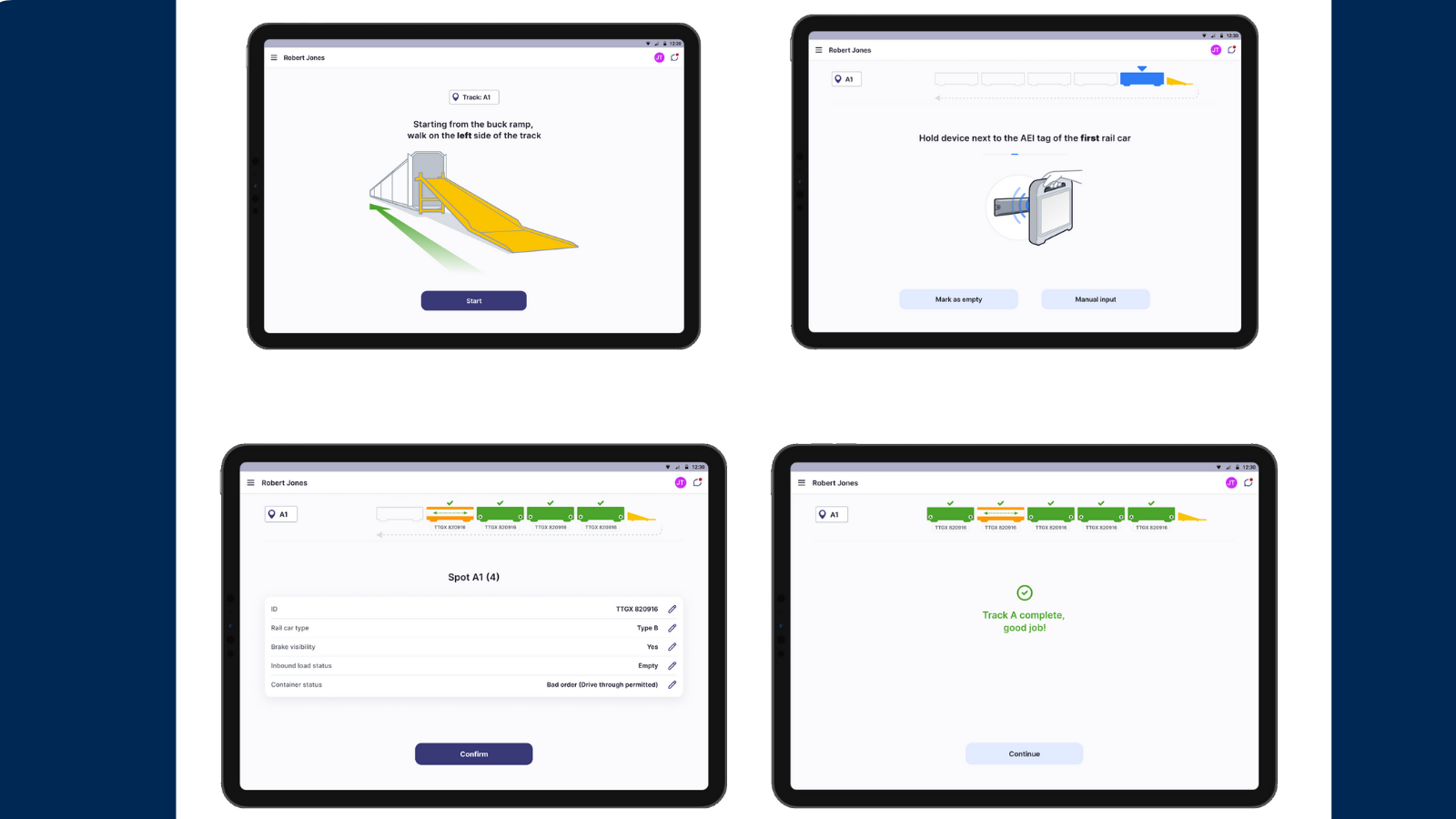

AutoVentive’s Yard Management System (YMS), which employs a telematics vehicle tracking system, automated this process, improving data accuracy and operational speed.

Results

Implementing AutoVentive’s YMS at Ford facilities has significantly improved the efficiency and safety of the railcar identification process. By automating the tracking and identification of railcars, the YMS has reduced human error and enhanced the overall reliability of data management.

AutoVentive’s YMS telematics tracking system helped Ford Motor Company identify where issues are happening and respond quickly.

This transition from manual to automated systems supports the brand’s commitment to technological advancement and sets a new standard for operational excellence in manufacturing.

Best Practices to Address Automotive Supply Chain Management Challenges

Ensuring the integrity of auto parts during transit is paramount to maintaining shipment quality. Traditional manual processes at assembly lines are slow and prone to human error, leading to potential discrepancies that can affect the entire supply chain.

Automating these processes is essential for mitigating risks, reducing errors and ensuring that every part shipped meets stringent industry-specific standards.

Here are several best practices in automation that can transform the supply chain operations:

- Integration of Automated Tracking Systems

Implementing systems like AutoVentive’s AV Track Sheets allows precise tracking of components throughout the supply chain. These systems use advanced scanning and geolocation technologies to monitor auto parts from assembly lines to delivery, significantly reducing the chance of misplacements and losses.

2. Utilization of Yard Management Systems (YMS)

Integrating AutoVentive’s YMS in automotive supply chain operations helps streamline field operations and enhance the quality control processes.

By automating the identification and tracking of shipments, the YMS ensures automotive parts are handled precisely, reducing the risk of damage and non-compliance. This process is crucial for maintaining supplier relations and providing a consistent supply of high-quality raw materials.

3. Standardization of Quality Control Protocols

Automation enables the standardization of inspection and quality control measures across the supply chain.

This consistency ensures that every part is inspected and verified against predefined standards, enhancing overall quality and reducing the variability that often comes with manual checks.

4. Real-Time Data Analytics

Leveraging real-time data from automated systems allows for immediate insights into the status and condition of shipments.

This capability enables proactive management of potential issues before they escalate, ensuring that all parts maintain their integrity throughout the transit process.

5. Enhanced Compliance Reporting

Automated systems streamline the documentation and reporting processes necessary for regulatory compliance. This action reduces the administrative burden and increases compliance report accuracy, helping safeguard the company against potential legal and financial penalties.

6. Risk Management Tools

Incorporating automation in the supply chain also includes sophisticated risk management tools that can predict and mitigate disruptions.

These tools analyze historical data and real-time inputs to forecast potential delays or quality issues. This data allows companies to implement contingency plans swiftly.

What are the benefits of implementing digital technologies in automotive supply chain solutions?

AutoVentive’s Track Sheets integrate cutting-edge digital technologies and analytics to enhance shipment quality and streamline supply chain operations. Below is a detailed exploration of the key features of AV Track Sheets and their specific benefits:

Handheld Rail Car Automatic Equipment Identification (AEI) Scanning

- Eliminates manual human errors in misreading rail car identifiers, which is crucial for maintaining high-quality standards.

- Resolves issues with graffiti and visibility that can obscure car identifiers, ensuring reliable data capture.

- Cuts track sheet generation time in half, boosting operational efficiency.

- Integrates with the Umler system to pull rail car types and mark bad orders, such as drive-through and non-loaders.

- Enables alerts for inbound embargoed rail cars and those marked for dismantling.

- Verifies track alignment with GPS and provides audio and vibration alerts, enhancing operator safety.

- Incorporates an integrated barcode scanner and camera for thorough surveys and inspections, enabling operators to perform tasks safely inside the vehicle.

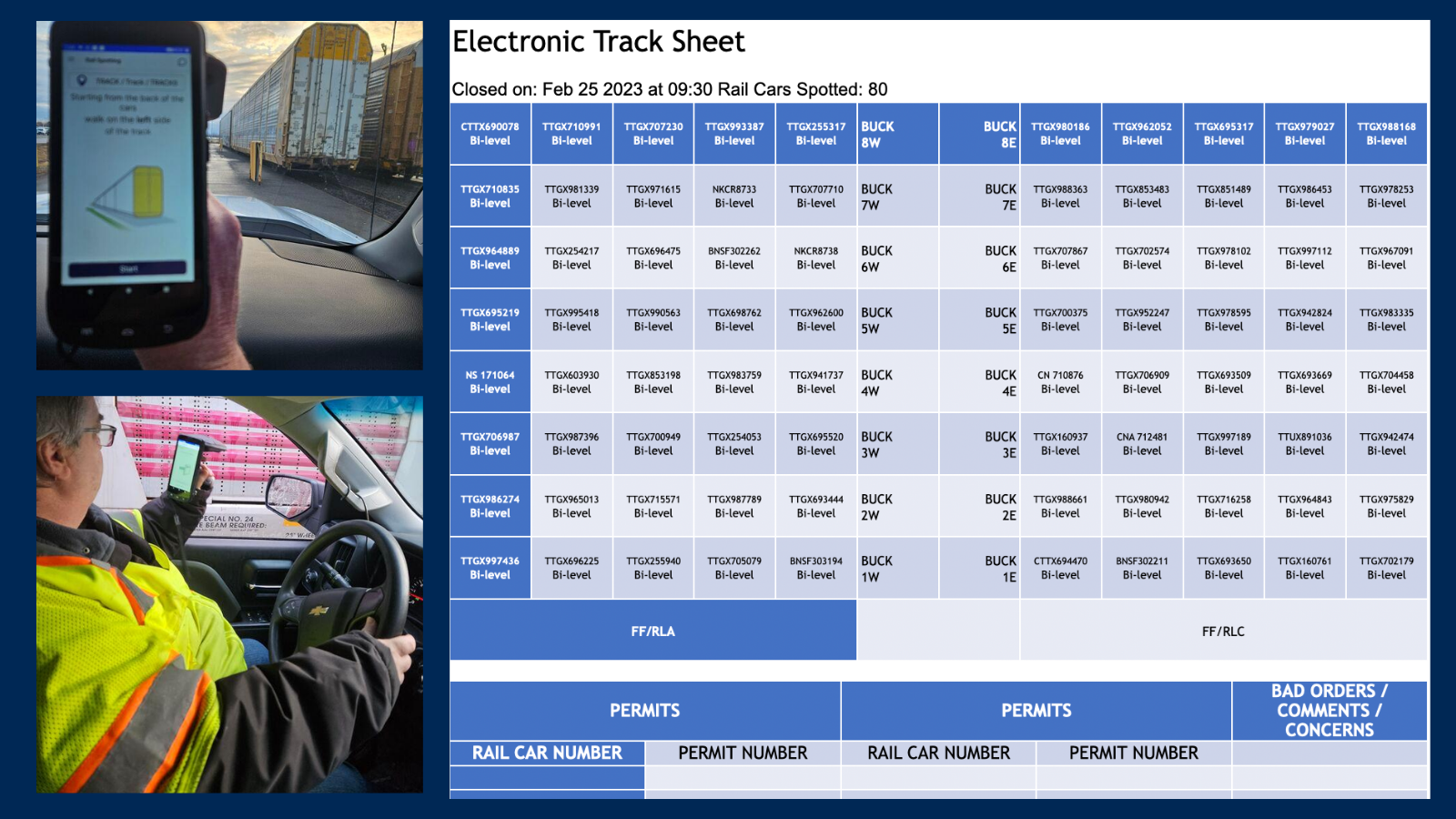

Automated Electronic Track Sheets

- Automatically sent to vested parties upon completion, facilitating timely updates and decision-making.

- Electronic storage aids in record-keeping and compliance reporting, enhancing transparency and accountability.

- Improves overall supply chain visibility, essential for optimizing operations and maintaining compliance with industry standards.

Geolocation Track Position Verification

- Conducts an initial one-time geo audit of rail tracks, guarding against incorrect track alignment and logistical errors.

- Assists in accurate spotting, loading and dispatching of shipments through GPS tracking verification, mitigating the risk of delays and errors.

- Ensures precise track alignment and correct positioning of rail cars, crucial for efficient transport.

Broader Implications and Future of Rail Yard Management Software

The positive impact of AutoVentive’s supply chain software at Ford facilities highlights its potential to enhance field operations across the automotive supply chain significantly.

AutoVentive YMS, a cloud-based solution compatible with industry-specific Android devices like the Zebra TC75 or L10, offers end-to-end visibility and analytics on all assets, shipments and workforce activities, enhancing the resiliency and sustainability of supply chains.

It can be accessed securely from any internet-connected computer or co-hosted on client-owned servers. This security adds a layer of flexibility and control for inventory management and complex logistics operations.

The ability to facilitate two-way data connectivity between web and handheld devices ensures timely, actionable information is always at hand. This capability is particularly valuable, enabling Ford to proactively address challenges without compromising cost-effectiveness.

As we move forward, the future of automotive supply chain solutions looks promising. Advanced technologies pave the way for more intelligent, responsive and efficient operations — businesses can maintain a competitive edge amidst the complexities of modern logistics.

Integrate AutoVentive’s Track Sheets as Your Automotive Supply Chain Solutions

AutoVentive’s AV Track Sheets significantly enhance the effectiveness of managing shipment quality and field operations. Improving accuracy, compliance and efficiency are crucial for modernizing automotive logistics, making them indispensable for those committed to excellence in automotive parts supply.

Request a demo and learn how AutoVentive’s rail yard management software can elevate your automotive logistics operations to meet the highest standards of quality and efficiency.